Naqshad Xirfadeed Shiinaha Warshadda Xirfadeed ee Sare ee Epoxy Fiberglass Laminate Sheet 3240 Fr4 G10

Tayada Sare Marka hore, Macaamiisha Sare waa tilmaamahayaga si aan macaamiisheenna ugu siino adeegga ugu faa'iidada badan. Waqtigan xaadirka ah, waxaan isku dayeynaa inaan ka mid noqono kuwa ugu sarreeya ee dhoofiya aaggeenna si aan u buuxinno baahiyaha badan ee iibsadayaasha Naqshadeynta Xirfadeed ee Warshadaha Xirfadeed ee Shiinaha ee Sare ee Epoxy Fiberglass Laminate Sheet 3240 Fr4 G10, Dhammaan alaabada waxaa lagu soo saaray qalab horumarsan iyo habab QC oo adag oo la iibsan karo si loo hubiyo tayo sare. Soo dhawoow macaamiisha cusub iyo kuwa da'da ah si aad noola soo xiriirto si aad iskaashi ganacsi u sameysato.

Tayada Sare Aad ugu horreysa, Consumer Supreme waa tilmaamahayaga si aan u siino adeegga ugu faa'iidada badan macaamiisheenna. Waqtigan xaadirka ah, waxaan isku dayeynaa inaan noqono kuwa ugu sarreeya ee dhoofiya aaggeenna si aan u daboolno baahida macaamiisha ee aadka u badan ee loo qabo.Xaashida Laminate Shiinaha, Dahaarka, Badeecadaha iyo xalalkayaga si weyn ayaa loo aqoonsan yahay oo ay ku kalsoon yihiin isticmaalayaashu waxayna dabooli karaan baahiyaha dhaqaale iyo bulsho ee sii kordhaya si joogto ah. Waxaan soo dhaweyneynaa macaamiisha cusub iyo kuwa hore ee ka kala yimid dhammaan qaybaha nolosha si ay noola soo xiriiraan si aan mustaqbalka xiriir ganacsi u yeelano una gaarno guul wadajir ah!

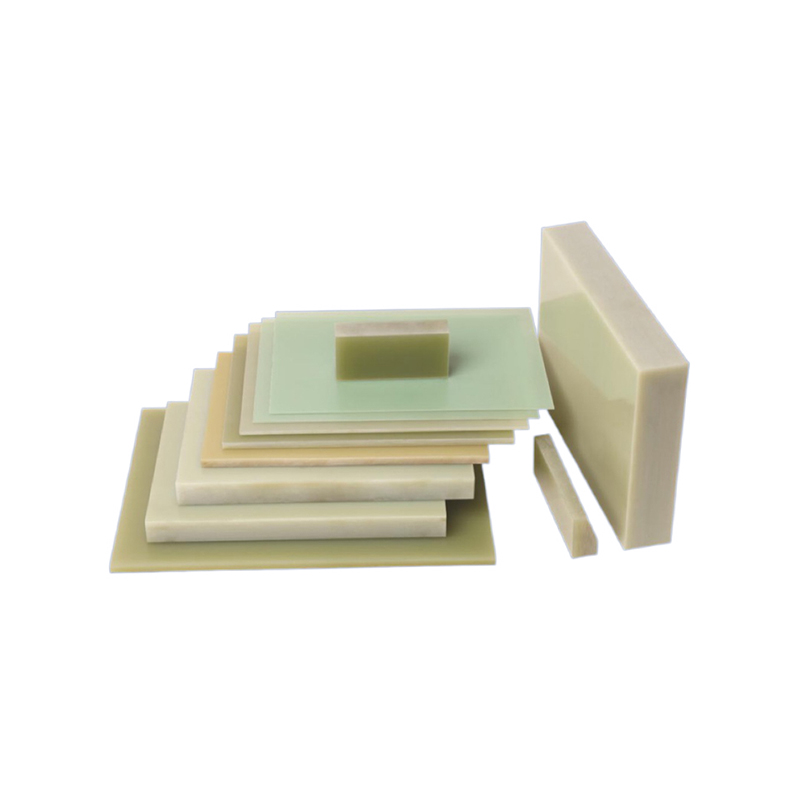

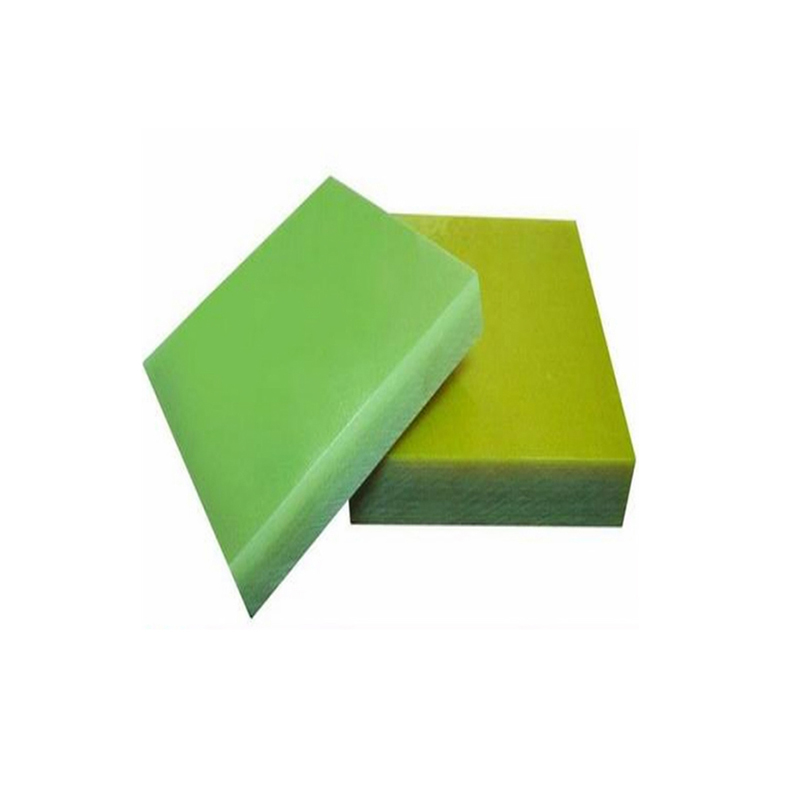

Taxanaha EPGC ee Epoxy Glass Maro adag oo la dahaadhay waxay ka kooban tahay maro galaas ah oo la tolay oo lagu dahaadhay resin thermoseting epoxy, oo lagu dahaadhay heerkul sare iyo cadaadis sare. Maro galaas ah oo la tolay waa inay ka madax bannaan tahay alkali oo lagu daaweeyaa isku xidhka silane. Xaashiyaha taxanaha ah ee EPGC waxaa ka mid ah EPGC201 (NMEMA G10), EPGC202(NEMA FR4), EPGC203(NEMA G11), EPGC204 (NEMA FR5), EPGC306 iyo EPGC308.

Xaashiyaha EPGC (fasalka kulaylka: B~H), oo la soo saaray sida waafaqsan IEC60893-3-2. Xaashiyahan waxay leeyihiin awood farsamo oo aad u fiican (heerka haynta xoogga heerkulka wuxuu gaari karaa in ka badan 50%) heerkulka dhexdhexaadka ah ama xaaladda kulaylka, iyo sidoo kale hantida korontada ee deggan (iska caabbinta dahaarka ka dib marka la dhex geliyo waxay gaartaa 1012Ω) xaalad qoyaan sare. Iyo sidoo kale iyadoo leh adkeysi koronto oo sarreeya / danab u adkaysta (in ka badan 35kV), oo barbar socda dahaarka. EPGC202, EPGC204 iyo EPGC306 sidoo kale waxay leeyihiin hanti aad u fiican oo ka hortagta ololka. Xaashiyaha sidoo kale waxay dhaafeen ogaanshaha walxaha sunta ah iyo kuwa khatarta ah (oo leh Warbixinta RoHS).

Waxaa loo isticmaalaa qaybaha dhismaha ee dahaarka ee matoorrada korantada ee fasalka BH, qalabka korontada, kuwaas oo leh shuruudo iska caabin olol ama aan lahayn, ama codsiyo kale.

Dhumucda la heli karo:0.30mm ~ 200mm

Cabbirka xaashida la heli karo:

1500mm*3000mm,1220mm*3000mm,1020mm*3000mm,1020mm*2440mm,1220mm*2440mm,1500mm*2440mm,1000mm*2000mm,1200mm*2000mm iyo cabbirro kale oo gorgortan ah.

Kala-soocidda iyo Nooca Xaashiyaha Epgc

| Nooca magaca | Codsiga & Sifada | Fasalka kulaylka | |||

| D&F | GB/IEC | NEMA | kuwa kale | ||

| DF201 | EPGC201 | G10 | Hgw 2372 | Makiinadaha, qalabka korontada iyo elektaroonada. Iyada oo leh xoog sare heerkulka dhexdhexaadka ah, iska caabin qaanso oo aad u fiican iyo PTI iyo CTI oo sarreeya | B 130℃ |

| DF202 | EPGC202 | FR-4 | Hgw 2372.1,F881 | Sida EPGC201 oo kale, lahaanshaha dab-damiye la sheegay. | B 130℃ |

| DF202A | — | — | — | Waxay la mid tahay DF202, laakiin leh awood farsamo oo sareysa. | B 130℃ |

| DF203 | EPGC203 | G11 | Hgw2372.4 | Qalabka farsamada, korontada iyo elektaroonada. Iyada oo leh xoogga ugu sarreeya heerkulka dhexe | F 155℃ |

| DF204 | EPGC204 | FR-5 | Hgw 2372.2 | Sida DF203 oo kale, lahaanshaha dab-damiye la sheegay. | F 155℃ |

| DF306 | EPGC306 | — | DF336 | Waxay la mid tahay DF203, waxayna leedahay iska caabin olol oo aad u fiican, iska caabin qaanso iyo PTI sare. | F 155℃ |

| DF306A | — | — | — | Waxay la mid tahay DF306, laakiin leh awood farsamo oo sare. | F 155℃ |

| DF308 | EPGC308 | — | — | Waxay la mid tahay DF203, laakiin leh xasillooni kuleyl oo wanaagsan. | Heerkulka sare 180℃ |

Shuruudaha Farsamada

Muuqaalka

Dusha sare ee xaashida waa inay ahaataa mid siman oo siman, ka xor ah xumbo hawo, laalaab ama dildilaacyo, isla markaana si macquul ah uga xor ah cillado yaryar sida xoqan, godad, iwm. Cidhifka xaashida waa inuu ahaadaa mid nadiif ah oo ka xor ah dildilaacyada iyo dildilaacyada. Midabku waa inuu ahaadaa mid isku mid ah, laakiin dhowr wasakh ayaa la oggol yahay.

Dhumucda magacaaban iyo dulqaadkaCutubka: mm

| Dhumucda magacaaban | Weecsanaan | Dhumucda Niminal | Weecsanaan |

| 0.5,0.6 0.8,1.0 1.2 1.5 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.15 +/-0.18 +/-0.21 +/-0.25 +/-0.30 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.85 +/-2.10 +/-2.45 +/-2.60 +/-2.80 |

| Faallooyin: Xaashiyaha dhumucdoodu aanay ahayn mid magac leh oo aan ku jirin Shaxdan, leexashada la oggol yahay waa inay la mid noqotaa tan dhumucda weyn ee xigta. | |||

Kala-leexashada Laabista ee XaashiyahaCutubka: mm

| Dhumucda | Kala-leexashada Laabista |

| 3.0~6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 |

Habaynta farsamada:

Go'yadu waa inay ka xoroobaan dildilaacyada iyo jajabyada marka la mariyo mishiinnada sida jarista, qodista, shiididda iyo shiididda.

Guryaha Jireed, Farsamo iyo Dielectric

| Maya. | Guryaha | Cutubka | EPGC201 | EPGC202 | EPGC203 | ||||

| Qiimaha caadiga ah | Qiimaha caadiga ah | Qiimaha caadiga ah | Qiimaha caadiga ah | Qiimaha caadiga ah | Qiimaha caadiga ah | ||||

| 1 | Nuugista biyaha (2mm xaashi) | mg | ≤20 | 8 | ≤20 | 9 | ≤20 | 9 | |

| 2 | Xoogga dabacsanaanta | Xaalad caadi ah | MPA | ≥340 | 460 | ≥340 | 500 | ≥340 | 450 |

| (Dherer ahaan) | 155℃+/-2℃ | — | — | — | — | ≥170 | 240 | ||

| 3 | Xoogga saameynta, oo la mid ah laminations (Charpy, notch) | kJ/m2 | ≥33 | 53 | ≥33 | 51 | ≥33 | 50 | |

| 4 | Xoog koronto, oo u janjeera laminations (saliidda transformer-ka 90℃+/-2℃) | kV/mm | ≥11.8 | 17 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Xoogga korontada, oo barbar socda lakabyada (saliidda beddelka 90℃+/-2℃) | kV | ≥35 | 48 | ≥35 | 45 | ≥35 | 45 | |

| 6 | Qodobka kala-baxa Dielectric (1MHz) | — | ≤0.04 | 0.02 | ≤0.04 | 0.02 | ≤0.04 | 0.021 | |

| 7 | Joogtada Dielectric (1MHz) | — | ≤5.5 | 4.8 | ≤5.5 | 4.7 | ≤5.5 | 4.7 | |

| 8 | Iska caabinta qaansada | s | — | — | — | 182 | — | 182 | |

| 9 | Iska caabbinta raadraaca caddaynta (PTI) | V | — | — | — | 600 | — | 600 | |

| 10 | Dahaarkaiska caabin ka dib marka biyaha lagu dhex qoyo | MΩ | ≥5.0 × 104 | 2.1 x107 | ≥5.0 × 104 | 1.5 x106 | ≥5.0 × 104 | 1.1 x107 | |

| 11 | Ololi kara | Fasal | — | — | V-0 | V-0 | — | — | |

| 12 | Tusmada Heerkulka (TI) | — | ≥130 | ≥130 | ≥155 | ||||

| Maya. | Guryaha | Cutubka | EPGC204 | EPGC306 | EPGC308 | ||||

| Qiimaha caadiga ah | Qiimaha caadiga ah | Qiimaha caadiga ah | Qiimaha caadiga ah | Qiimaha caadiga ah | Qiimaha caadiga ah | ||||

| 1 | Nuugista biyaha (2mm) | mg | ≤20 | 11 | ≤20 | 8 | ≤20 | 9 | |

| 2 | Xoogga dabacsanaanta | Xaalad caadi ah | MPA | ≥340 | 480 | ≥340 | 460 | ≥340 | 500 |

| (Dhereer ahaan) | 155℃+/-2℃ | ≥170 | 260 | ≥170 | 280 | — | 270 | ||

| 3 | Xoogga saameynta, oo la mid ah laminations (Charpy, notch) | kJ/m2 | ≥33 | 51 | ≥33 | 53 | ≥33 | 52 | |

| 4 | Xoog koronto, oo u janjeera laminations (saliidda transformer-ka 90℃+/-2℃) | kV/mm | ≥11.8 | 16 | ≥11.8 | 17 | ≥11.8 | 18 | |

| 5 | Xoogga korontada, oo barbar socda lakabyada (saliidda beddelka 90℃+/-2℃) | kV | ≥35 | 45 | ≥35 | 48 | ≥35 | 45 | |

| 6 | Qodobka kala-baxa Dielectric (1MHz) | — | ≤0.04 | 0.018 | ≤0.04 | 0.02 | ≤0.04 | 0.02 | |

| 7 | Joogtada Dielectric (1MHz) | — | ≤5.5 | 4.7 | ≤5.5 | 4.8 | ≤5.5 | 4.7 | |

| 8 | Iska caabinta qaansada | s | — | — | — | 182 | — | — | |

| 9 | Iska caabbinta raadraaca caddaynta (PTI) | V | — | — | — | 600 | — | — | |

| 10 | Iska caabbinta dahaarka ka dib marka biyaha lagu dhex milmo | MΩ | ≥5.0 × 104 | 3.8 x106 | ≥5.0 × 104 | 1.8 x107 | ≥5.0 × 104 | 7.1 x106 | |

| 11 | Ololi kara | Fasal | V-0 | V-0 | V-0 | V-0 | — | — | |

| 12 | Tusmada Heerkulka (TI) | — | ≥155 | ≥155 | ≥180 | ||||

Baakaynta iyo Kaydinta

Go'yaasha waa in lagu kaydiyaa meel heerkulkeedu aanu ka badnayn 40℃, waana in si toosan loo saaraa saxan sariireed oo dhererkiisu yahay 50mm ama ka sarreeya. Ka fogow dabka, kulaylka (qalabka kululaynta) iyo qorraxda tooska ah. Cimriga kaydinta ee go'yaasha waa 18 bilood laga bilaabo taariikhda ka bixitaanka warshadda. Haddii muddada kaydinta ay ka badan tahay 18 bilood, badeecada ayaa sidoo kale la isticmaali karaa ka dib marka la tijaabiyo si loogu qalmo.

Faallooyinka iyo Taxaddarrada Codsiga

1 Mashiinku waa inuu u hoggaansamo JB/Z141-1979,Hababka mashiinka ee alaabada dahaaran ee dahaarka leh, sababtoo ah xaashiduhu waxay leeyihiin farqi u dhexeeya sifada ka timid birta.

2 Xawaar sare iyo qoto dheer oo jarid yar ayaa la isticmaali doonaa marka la farsamaynayo sababtoo ah kulaylka oo daciif ah oo xaashida ah.

3 Mashiinka iyo jarista badeecadan waxay sii deyn doontaa boodh iyo qiiq badan. Tallaabooyin ku habboon waa in la qaadaa si loo hubiyo in heerarka boorku ay ku jiraan xadka la aqbali karo inta lagu jiro hawlgallada. Hawada qiiqa ee maxalliga ah iyo isticmaalka maaskaro ku habboon boodhka/qaybta ayaa lagula talinayaa.

4 Go'yaasha waxaa la saari karaa qoyaan ka dib marka la mariyo, waxaa lagu talinayaa in lagu dahaadho dahaarka dahaarka leh.

Qalabka Wax Soo Saarka

Xirmada Xaashiyaha EPGC

Tayada Sare Marka hore, Macaamiisha Sare waa tilmaamahayaga si aan macaamiisheenna ugu siino adeegga ugu faa'iidada badan. Waqtigan xaadirka ah, waxaan isku dayeynaa inaan ka mid noqono kuwa ugu sarreeya ee dhoofiya aaggeenna si aan u buuxinno baahiyaha badan ee iibsadayaasha Naqshadeynta Xirfadeed ee Warshadaha Xirfadeed ee Shiinaha ee Sare ee Epoxy Fiberglass Laminate Sheet 3240 Fr4 G10, Dhammaan alaabada waxaa lagu soo saaray qalab horumarsan iyo habab QC oo adag oo la iibsan karo si loo hubiyo tayo sare. Soo dhawoow macaamiisha cusub iyo kuwa da'da ah si aad noola soo xiriirto si aad iskaashi ganacsi u sameysato.

Naqshad XirfadeedXaashida Laminate Shiinaha, Dahaarka, Badeecadaha iyo xalalkayaga si weyn ayaa loo aqoonsan yahay oo loogu kalsoon yahay isticmaalayaashu waxayna dabooli karaan baahiyaha dhaqaale iyo bulsho ee sii kordhaya si joogto ah. Waxaan soo dhaweyneynaa macaamiisha cusub iyo kuwa duugga ah ee ka kala yimid dhammaan qaybaha nolosha si ay noola soo xiriiraan si ay mustaqbalka xiriir ganacsi u yeeshaan una gaaraan guul wadajir ah!