GPO-3 (UPGM203) Muraayad Polyester ah oo aan dheregsanayn oo lagu dahaadhay warqad dahaaran

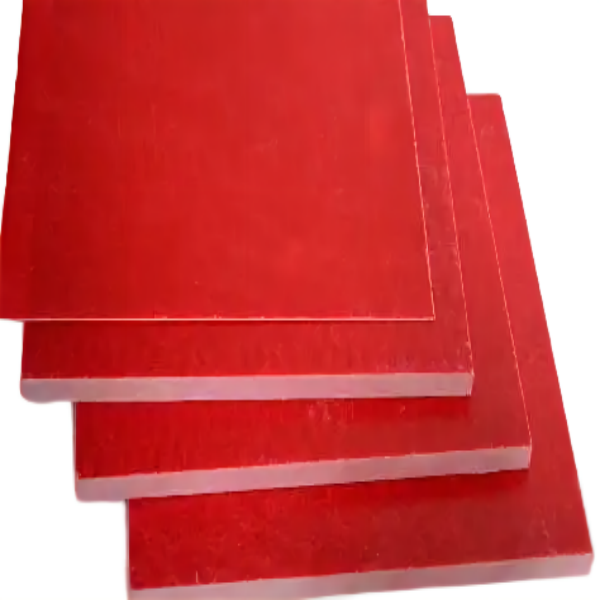

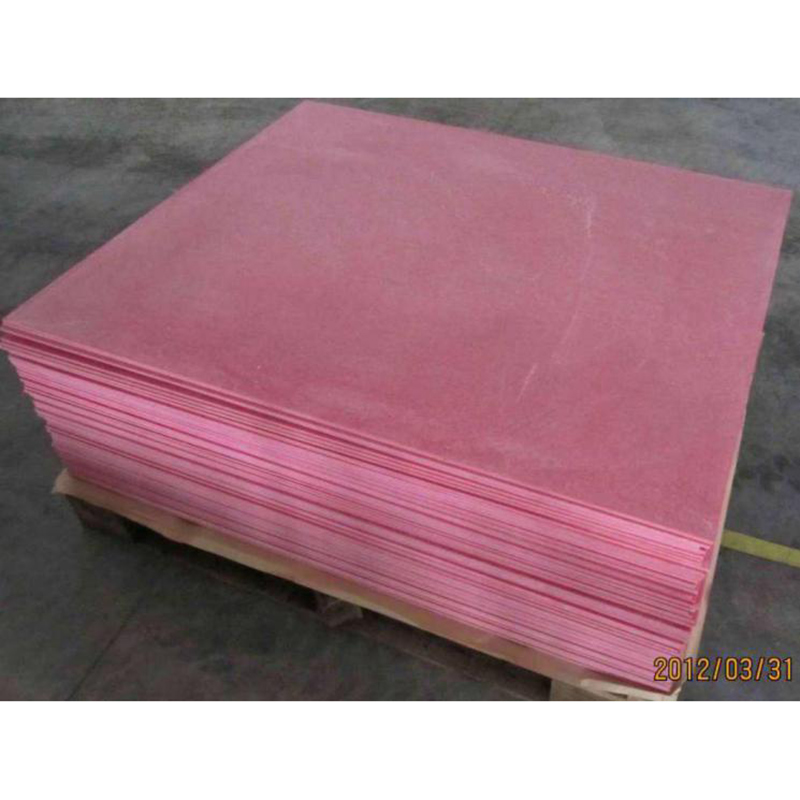

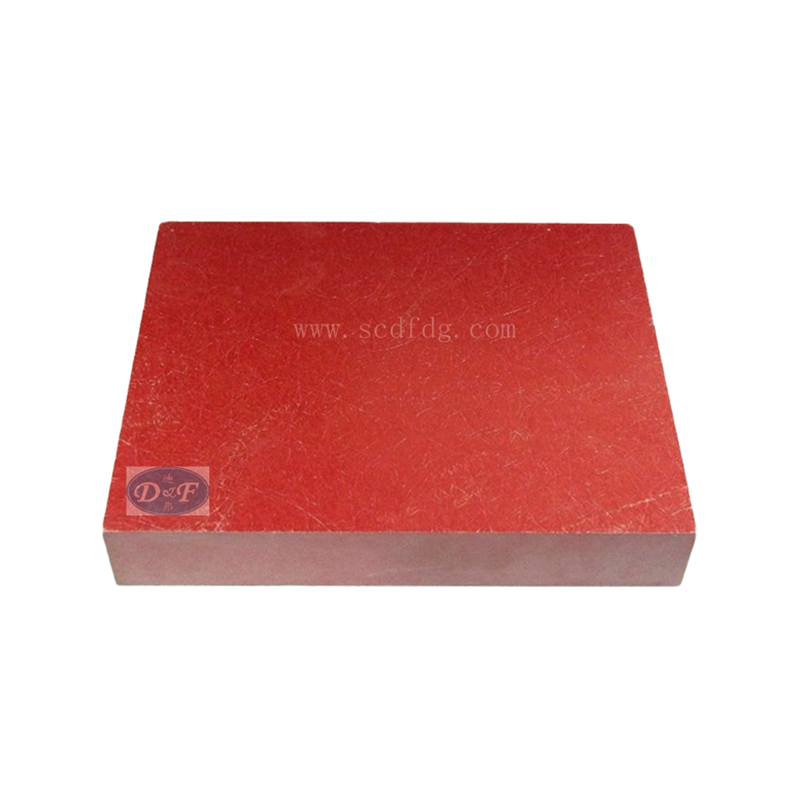

Xaashida la qaabeeyey ee GPO-3 (oo sidoo kale loo yaqaan GPO3, UPGM203) waxay ka kooban tahay roogag galaas oo aan alkali lahayn oo lagu shubay oo lagu xidhay resin polyester-ka aan buuxin, waxaana lagu dahaadhay heerkul sare iyo cadaadis sare oo caaryada ah. Waxay leedahay mashiin wanaagsan, xoog farsamo oo sare, sifooyin dielectric wanaagsan, iska caabin raadraac oo heer sare ah iyo iska caabin qaanso. Waxay leedahay shahaadada UL waxayna ka gudubtay tijaabada REACH iyo RoHS, iwm. Waxaa sidoo kale loo yaqaan guddiga dahaarka GPO-3 ama GPO3, GPO-3 ama guddiga dahaarka GPO3.

Waxay khuseysaa sameynta qaybaha qaab-dhismeedka iyo taageerada ee dahaarka ama qaybaha matoorada korontada ee fasalka F, transformers-ka, qalabka badalka, qalabka jebiya wareegyada iyo qalabka korontada. UPGM-ka waxaa si toos ah loogu qaabeyn karaa astaamo kala duwan ama qaybo qaab-dhismeed oo dahaarka ah.

Kala duwanaanshaha dhumucda:2mm---60mm

Cabbirka xaashida:1020mm *2010mm, 1000mm *2000mm, 1220mm *2440mm iyo dhumucdiis kale oo gorgortan ah ama/iyo cabbirro

Midabka ugu muhiimsanmidabyo casaan, caddaan ama midabyo kale oo gorgortan ah

Marka laga soo tago xaashida la dahaadhay ee UPGM, waxaan sidoo kale soo saarnaa oo bixinnaa xaashida EPGM 203, cabbirka xaashidu waa la mid yahay kuwa GPO-3. Midabku waa huruud ama cagaar. Fadlan ila soo xiriir si aad u hesho macluumaad dheeraad ah.

Shuruudaha Farsamada

Muuqaalka

Dusha sare waa inay ahaataa mid siman oo siman, ka xor ah finanka, laalaabyada ama dildilaaca, isla markaana si macquul ah uga xor ah cilladaha yaryar sida xoqidda, godadka iyo midabada aan sinnayn.

Caadi tqallafsanaanta iyodulqaad

| Dhumucda Magacaaban (mm) | Dulqaad la oggol yahay (mm) | Dhumucda Magacaaban (mm) | Dulqaad la oggol yahay (mm) | |

| 0.8 | +/-0.23 | 12 | +/-0.90 | |

| 1.0 | +/-0.23 | 14 | +/-1.00 | |

| 2.0 | +/-0.30 | 16 | +/-1.10 | |

| 3.0 | +/-0.35 | 20 | +/-1.30 | |

| 4.0 | +/-0.40 | 25 | +/-1.40 | |

| 5.0 | +/-0.55 | 30 | +/-1.45 | |

| 6.0 | +/-0.60 | 40 | +/-1.55 | |

| 8.0 | +/-0.70 | 50 | +/-1.75 | |

| 10.0 | +/-0.80 | 60 | +/-1.90 | |

| Fiiro gaar ah: Xaashiyaha dhumucdoodu aanay ahayn mid magac leh oo aan ku jirin jadwalkan, leexashada la oggol yahay waa inay la mid noqotaa tan dhumucda weyn ee xigta. | ||||

Sifooyinka jireed, farsamo iyo koronto

| Guryaha | Cutubka | Qiimaha caadiga ah | Qiimaha caadiga ah | Habka tijaabada | ||

| Cufnaanta | g/cm3 | 1.65~1.95 | 1.8 | GB/T 1033.1-2008 | ||

| (Habka A) | ||||||

| Nuugista biyaha, dhumucdiisuna tahay 3mm | % | ≤ 0.2 | 0.16 | ASTM D790-03 | ||

| Xoogga laalaabka, oo si toosan ugu toosan laminations (Dhererka) | Xaalad caadi ah | MPA | ≥180 | 235 | ASTM D790-03 | |

| 130℃+/-2℃ | ≥100 | 144 | ||||

| Modulus-ka dabacsan, oo ku toosan lakabyada (Dhererka) | Xaalad caadi ah | MPA | - | 1.43 x 104 | ||

| 130℃+/-2℃ | - | 1.10 x 104 | ||||

| Xoogga laalaabka, oo si toosan ugu toosan laminations (Dhererka) | Dhirir ahaan | MPA | ≥170 | 243 | GB/T 1449-2005 | |

| Isgoysyada | ≥150 | 240 | ||||

| Xoogga Saamaynta, oo la barbar socda laminations | KJ/m2 | ≥40 | 83.1 | GB/T 1043.1-2008 | ||

| (Carpy, aan la jarin) | ||||||

| Xoogga Saamaynta, oo la barbar socda laminations | J/m | - | 921 | ASTM D256-06 | ||

| (Izod, la jarjaray) | ||||||

| Xoogga jiidista | MPA | ≥150 | 165 | GB/T 1040.2-2006 | ||

| Modulus-ka dabacsanaanta jilicsanaanta | MPA | ≥1.5x104 | 1.7 x 104 | |||

| Xoogga jiidista, oo la mid ah laminations | Dhirir ahaan | MPA | ≥55 | 165 | GB/T1447-2005 | |

| Isgoysyada | ≥55 | 168 | ||||

| Daba-joog u ah laminations-ka | MPA | - | 230 | ASTM D695-10 | ||

| Xoogga cadaadiska | ||||||

| Xoogga Dielectric, oo si toosan ugu toosan lakabyada (25 # saliidda transformer-ka 90℃+/-2℃, tijaabo waqti-gaaban ah, elektroodka dhululubada Φ25mm/Φ75mm) | KV/mm | ≥12 | 135 | IEC60243-1:2013 | ||

| Danabka burburka, oo la mid ah laminations (oo ku jira 25 # saliidda transformer-ka 90℃+/-2℃, tijaabo waqti-gaaban ah, elektroodka saxanka Φ130mm/Φ130mm) | KV | ≥35 | >100 | |||

| Ogolaanshaha qaraabada ah (1MHz) | - | ≤ 4.8 | 4.54 | GB/T 1409-2006 | ||

| Qodobka kala-baxa Dielectric (1MHz) | - | ≤ 0.03 | 1.49 x 10-2 | |||

| Iska caabinta Qaanso | s | ≥180 | 187 | GB/T 1411-2002 | ||

| Iska caabinta raadraaca | CTI | V | ≥600 | CTI 600 | ||

| Buundada Xadka ah | GB/T 4207-2012 | |||||

| PTI | ≥600 | PTI 600 | ||||

| Iska caabinta dahaarka | Xaalad caadi ah | Ω | ≥1.0x1013 | 5.4 x 1014 | GB/T 10064-2006 | |

| (Elektaroodhada biinanka ee taper) | Kadib 24 saacadood oo biyo ah | ≥1.0x1012 | 2.5 x 1014 | |||

| Ololi kara (Habka Toosan) | Fasal | V-0 | V-0 | UL94-2013 | ||

| Silig iftiin leh | - | - | GWIT:960/3.0 | GB/T5169.13-2006 | ||

| Adkaanshaha Barcol | - | ≥ 55 | 60 | ASTM D2583-07 | ||

Kormeerka, Calaamadda, Baakadaha iyo Kaydinta

1) Dufcad kasta waa in la tijaabiyaa ka hor inta aan la dirin. Shayada kormeerka ee Imtixaanka Caadiga ah waa inay ku jiraan Qodobbada 2.1, 2.2, iyo Qodobka 1 iyo Qodobka 3 ee Shaxda 6 ee Qodobbada 2.3. Shayada ku jira Qodobbada 2.1, 2.2, waa in mid mid loo hubiyaa.

2) Go'yaasha waa in lagu kaydiyaa meel heerkulkeedu aanu ka badnayn 40℃, waana in si toosan loo saaraa saxan sariireed oo dhererkiisu yahay 50mm ama ka sarreeya. Ka fogow dabka, kulaylka (qalabka kululaynta) iyo qorraxda tooska ah. Muddada kaydinta ee go'yaasha waa 18 bilood laga bilaabo taariikhda ka bixitaanka warshadda. Haddii muddada kaydinta ay ka badan tahay 18 bilood, badeecada sidoo kale waa la isticmaali karaa ka dib marka la tijaabiyo si loogu qalmo.

Faallooyin iyo Taxaddarro ku saabsan Maareynta iyo Isticmaalka

1) Xawaare sare iyo qoto dheer oo jarid ah waa in la adeegsadaa marka la farsamaynayo sababtoo ah kulaylka oo daciif ah oo waraaqaha ku jira.

2) Mashiinka iyo jarista badeecadan waxay sii deyn doontaa boodh iyo qiiq badan. Tallaabooyin ku habboon waa in la qaadaa si loo hubiyo in heerarka boorku ay ku jiraan xadka la aqbali karo inta lagu jiro hawlgallada. Hawada qiiqa ee maxalliga ah iyo isticmaalka maaskaro ku habboon oo loogu talagalay boodhka/qaybta.

Shahaadada