Warqad dahaarka D370 SMC ah oo la qaabeeyey

Xaashida dahaarka ee D370 SMC ee la qaabeeyey waa nooc ka mid ah xaashida dahaarka ee adag ee kuleylka dejisa. Waxaa laga sameeyay SMC iyadoo lagu sameeyay caaryo heerkul sare iyo cadaadis sare. Waxay leedahay shahaadada UL waxayna ka gudubtay tijaabada REACH iyo RoHS, iwm. Waxaa sidoo kale loo yaqaannaa xaashida SMC, guddiga dahaarka ee SMC, iwm.

SMC waa nooc ka mid ah isku-dhafka xaashida oo ka kooban faybar galaas ah oo lagu xoojiyay resin polyester aan dheregsanayn, oo lagu buuxiyay wax-ka-qabashada dabka iyo walxo kale oo buuxin ah.

Xaashiyaha SMC waxay leeyihiin xoog farsamo oo sarreeya, xoog dielectric ah, iska caabin olol wanaagsan, iska caabin raadraac ah, iska caabin qaanso iyo danab u adkaysi sare leh, iyo sidoo kale nuugista biyaha oo hooseeya, dulqaad cabbir deggan iyo leexasho yar oo foorarsi ah. Xaashiyaha SMC waxaa loo isticmaalaa sameynta dhammaan noocyada looxyada dahaarka leh ee ku jira gears-ka beddelayaasha danabka sare ama hooseeya. Waxa kale oo loo isticmaali karaa in lagu farsameeyo qaybaha kale ee dhismaha dahaarka.

Dhumucda: 2.0mm ~ 60mm

Cabbirka xaashida: 580mm * 850mm, 1000mm * 2000mm, 1300mm * 2000mm, 1500mm * 2000mm ama cabbirro kale oo gorgortan ah

SMC

DMC

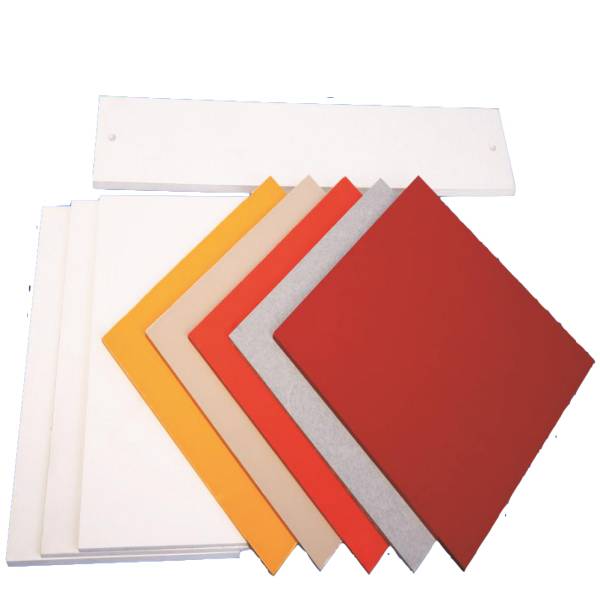

Xaashiyaha SMC oo leh midab kala duwan

Xaashiyaha SMC

Shuruudaha Farsamada

Muuqaalka

Dusha sare waa inay ahaataa mid siman oo siman, oo aan lahayn finan, godad iyo waxyeello farsamo oo muuqata. Midabka dusha sare waa inuu ahaadaa mid isku mid ah, oo aan lahayn faybar muuqda. Ka xor ah wasakhda muuqata, wasakhda iyo godadka muuqda. Ka xor ah dildilaaca iyo dildilaaca geesaha. Haddii ay jiraan cillado dusha sare ee badeecada, waa la hagaajin karaa. Dambaska aadka u badan waa in la nadiifiyaa.

bleexashada dhammaadkaCutubka: mm

| Faahfaahin gaar ah | Cabbirka qaabka | Dhumucda magacaaban S | Leexashada leexashada | Dhumucda magacaaban S | Leexashada leexashada | Dhumucda magacaaban S | Leexashada leexashada |

| Xaashida D370 SMC | Dhererka dhammaan dhinacyada ≤500 | 3≤S<5 | ≤8 | 5≤S<10 | ≤5 | ≥10 | ≤4 |

| Dhererka dhinac kasta | 3≤S<5 | ≤12 | 5≤S<10 | ≤8 | ≥10 | ≤6 | |

| 500 ilaa 1000 | |||||||

| Dhererka dhinac kasta ≥1000 | 3≤S<5 | ≤20 | 5≤S<10 | ≤15 | ≥10 | ≤10 |

Shuruudaha waxqabadka

Sifooyinka jireed, farsamo iyo koronto ee xaashiyaha SMC

| Guryaha | Cutubka | Qiimaha caadiga ah | Qiimaha caadiga ah | Habka tijaabada | ||

| Cufnaanta | g/cm3 | 1.65—1.95 | 1.79 | GB/T1033.1-2008 | ||

| Adkaanshaha Barcol | - | ≥ 55 | 60 | ASTM D2583-07 | ||

| Nuugista biyaha, dhumucdiisuna tahay 3mm | % | ≤0.2 | 0.13 | GB/T1034-2008 | ||

| Xoogga dabacsanaanta, oo si toosan ugu toosan laminations | Dhirir ahaan | MPA | ≥170

| 243 | GB/T1449-2005 | |

| Isgoysyada | ≥150 | 240 | ||||

| Xoogga Saamaynta, oo barbar socda lakabyada (Charpy, aan la kala saarin) | KJ/m2 | ≥60 | 165 | GB/T1447-2005 | ||

| Xoogga jiidista | MPA | ≥55 | 143 | GB/T1447-2005 | ||

| Modulus-ka dabacsanaanta jilicsanaanta | MPA | ≥9000 | 1.48 x 104 | |||

| Hoos u dhaca wax lagu sameeyo | % | - | 0.07 | ISO2577:2007 | ||

| Xoog cadaadis leh (oo si toos ah ugu toosan laminations) | MPA | ≥ 150 | 195 | GB/T1448-2005 | ||

| Modulus cadaadis leh | MPA | - | 8300 | |||

| Heerkulka leexashada kulaylka ee culayska saaran (T)ff1.8) | ℃ | ≥190 | >240 | GB/T1634.2-2004 | ||

| Isugeynta ballaarinta kulaylka dahaarka (20℃ --40℃) | 10-6/K | ≤18 | 16 | ISO11359-2-1999 | ||

| Xoogga korontada (25 # saliidda transformer-ka 23℃+/-2℃, tijaabo waqti-gaaban ah, Φ25mm/Φ75mm, elektroodh dhululubo ah) | KV/mm | ≥12 | 15.3 | GB/T1408.1-2006 | ||

| Danabka burburka (oo barbar socda lakabyada, saliidda beddelka 25 # ee 23℃+/-2℃, tijaabada tallaabo-tallaabo ee 20-meeyada, Φ130mm/Φ130mm, elektroodka saxanka) | KV | ≥25 | >100 | GB/T1408.1-2006 | ||

| Iska caabinta mugga | Ω.m | ≥1.0 x 1012 | 3.9 x 1012 | GB/T1408.1-2006 | ||

| Iska caabinta dusha sare | Ω | ≥1.0 x 1012 | 2.6 x 1012 | |||

| Ogolaanshaha qaraabada ah (1MHz) | - | ≤ 4.8 | 4.54 | GB/T1409-2006 | ||

| Qodobka kala-baxa Dielectric (1MHz) | - | ≤ 0.06 | 9.05 x 10-3 | |||

| Iska caabinta Qaanso | s | ≥180 | 181 | GB/T1411-2002 | ||

| Iska caabinta raadraaca | CTI

| V | ≥600 | 600 Buundada Xadka ah | GB/T1411-2002

| |

| PTI | ≥600 | 600 | ||||

| Iska caabinta dahaarka | Xaalad caadi ah | Ω | ≥1.0 x 1013 | 3.0 x 1014 | GB/T10064-2006 | |

| Kadib 24 saacadood oo biyo ah | ≥1.0 x 1012 | 2.5 x 1013 | ||||

| Ololi kara | Fasal | V-0 | V-0 | UL94-2010 | ||

| Tusmada oksijiinta | ℃ | ≥ 22 | 32.1 | GB/T2406.1 | ||

| Tijaabada siligga iftiinka | ℃ | >850 | 960 | IEC61800-5-1 | ||

U adkeysan danab

| Dhumucda magacaaban (mm) | 3 | 4 | 5~6 | >6 |

| U adkeysan kara danabka hawada ku jira muddo 1 daqiiqo ah KV | ≥25 | ≥33 | ≥42 | >48 |

Kormeerka, Calaamadda, Baakadaha iyo Kaydinta

1. Dufcad kasta waa in la tijaabiyaa ka hor inta aan la dirin.

2. Sida waafaqsan shuruudaha macaamiisha, habka tijaabada ee danab u adkeysiga waa la gorgortami karaa iyadoo loo eegayo xaashida ama qaababka.

3. Waxaa lagu soo buuxiyaa sanduuq kartoon ah oo ku yaal baakadda. Miisaankiisu kama badna 500kg baaldigiiba.

4. Bacaha waa in lagu kaydiyaa meel heerkulkeedu aanu ka sarreyn 40℃, waana in si toosan loo saaraa sagxad sariireed oo dhererkeedu yahay 50mm ama ka sarreeya. Ka fogow dabka, kulaylka (qalabka kululaynta) iyo qorraxda tooska ah. Cimriga kaydinta ee bacaha waa 18 bilood laga bilaabo taariikhda ka bixitaanka warshadda. Haddii muddada kaydinta ay ka badan tahay 18 bilood, badeecada ayaa sidoo kale la isticmaali karaa ka dib marka la tijaabiyo si loogu qalmo.

5. Kuwa kale waa inay raacaan shuruudaha GB/T1305-1985,Xeerarka guud ee loogu talagalay kormeerka, calaamadaha, baakadaha, rarista iyo kaydinta walxaha kuleyliyaha dahaarka leh.

Shahaadada