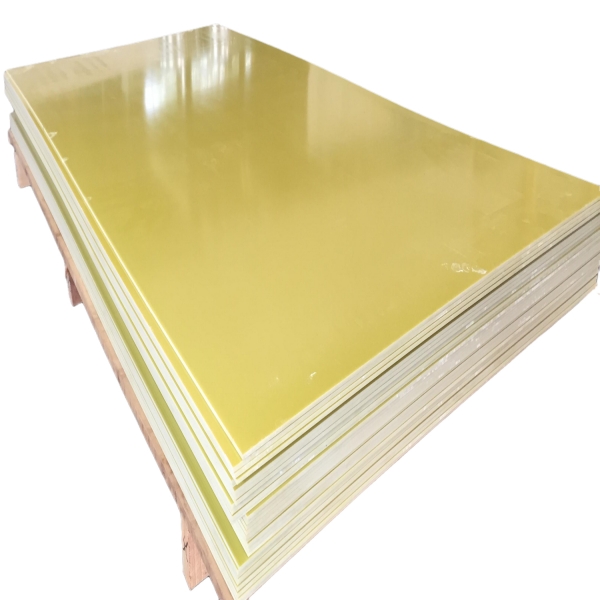

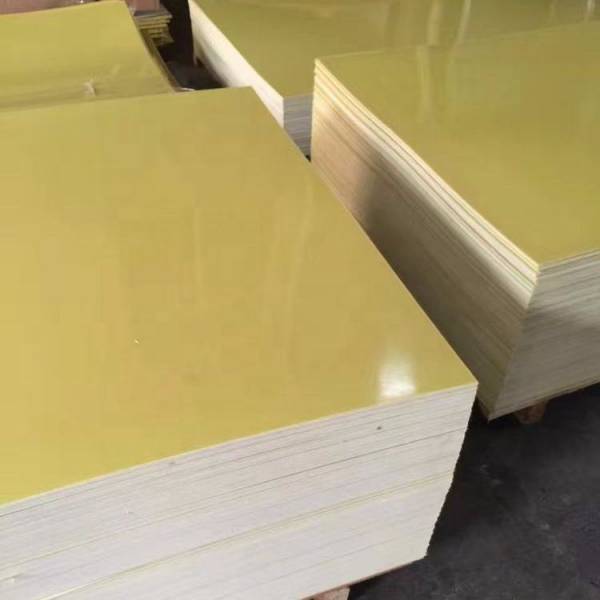

3240 Epoxy Phenolic Glass Maro Saldhigga Xaashi adag oo la dahaadhay

Shuruudaha Farsamada

1.1Muuqaalka:Dusha sare ee xaashida waa inay ahaataa mid siman oo siman, ka xor ah xumbo hawo, laalaab ama dildilaacyo, isla markaana si macquul ah uga xor ah cillado yaryar sida xoqan, godad, iwm. Cidhifka xaashida waa inuu ahaadaa mid nadiif ah oo ka xor ah dildilaacyo iyo dildilaacyo. Midabku waa inuu ahaadaa mid isku mid ah, laakiin dhowr wasakh ayaa la oggol yahay.

1.2Cabbirka iyo loo oggol yahaydulqaad

1.2.1 Ballaca iyo Dhererka Waraaqaha

| Ballaca iyo Dhererka (mm) | Dulqaadka (mm) |

| >970~3000 | +/- 25 |

1.2.2 Dhumucda magacaaban iyo dulqaadka

| Dhumucda magacaaban (mm) | Dulqaadka (mm) | Dhumucda magacaaban (mm) | Dulqaadka (mm) |

| 0.5 0.6 0.8 1.0 1.2 1.6 2.0 2.5 3.0 4.0 5.0 6.0 8.0 | +/-0.12 +/-0.13 +/-0.16 +/-0.18 +/-0.20 +/-0.24 +/-0.28 +/-0.33 +/-0.37 +/-0.45 +/-0.52 +/-0.60 +/-0.72 | 10 12 14 16 20 25 30 35 40 45 50 60 80 | +/-0.82 +/-0.94 +/-1.02 +/-1.12 +/-1.30 +/-1.50 +/-1.70 +/-1.95 +/-2.10 +/-2.30 +/-2.45 +/- 2.50 +/-2.80 |

| Faallooyin: Dhumucda aan magaca lahayn ee aan ku jirin jadwalkan, leexashadu waxay la mid noqon doontaa tan dhumucda weyn ee xigta. | |||

1.3Kala-leexashada Laabista

| Dhumuc (mm) | Kala-leexashada Laabista | |

| 1000mm (Dhererka taliye) (mm) | 500mm (Dhererka taliye) (mm) | |

| 3.0~6.0 >6.0~8.0 >8.0 | ≤10 ≤8 ≤6 | ≤2.5 ≤2.0 ≤1.5 |

1.4Habaynta farsamada:Gooyadu waa inay ka xoroobaan dildilaacyada, jajabyada iyo qashinka marka la mariyo mishiinnada sida jarista, qodista, shiididda iyo shiididda.

1.5Sifooyinka jireed, farsamo iyo koronto

| Maya. | Guryaha | Cutubka | Qiimaha caadiga ah | Qiimaha caadiga ah |

| 1 | Cufnaanta | g/cm3 | 1.7~1.95 | 1.94 |

| 2 | Nuugista biyaha (2mm xaashi) | mg | ≤20 | 5.7 |

| 3 | Xoogga dabacsanaanta, oo ku toosan laminations-ka | MPA | ≥340 | 417 |

| 4 | Xoogga saameynta (Charpy, notch) | kJ/m2 | ≥30 | 50 |

| 5 | Qodobka kala-baxa Dielectric 50Hz | --- | ≤5.5 | 4.48 |

| 6 | Joogtada Dielectric 50Hz | --- | ≤0.04 | 0.02 |

| 7 | Iska caabbinta dahaarka (Ka dib 24 saacadood oo biyo ah) | Ω | ≥5.0 x108 | 4.9 x109 |

| 8 | Xoogga Dielectric, oo ku toosan saliidda transformer-ka laminationsin ee 90℃+/-2℃, xaashida 1mm | kV/mm | ≥14.2 | 16.8 |

| 9 | Danab burburay, oo barbar socda saliidda transformer-ka laminationsin ee 90℃+/-2℃ | kV | ≥35 | 38 |

Baakadeynta, Gaadiidka iyo Kaydinta

Go'yaasha waa in lagu kaydiyaa meel heerkulkeedu aanu ka badnayn 40℃, waana in si toosan loo saaraa saxan sariireed oo dhererkiisu yahay 50mm ama ka sarreeya. Ka fogow dabka, kulaylka (qalabka kululaynta) iyo qorraxda tooska ah. Cimriga kaydinta ee go'yaasha waa 18 bilood laga bilaabo taariikhda ka bixitaanka warshadda. Haddii muddada kaydinta ay ka badan tahay 18 bilood, badeecada ayaa sidoo kale la isticmaali karaa ka dib marka la tijaabiyo si loogu qalmo.

Faallooyin iyo Taxaddarro ku saabsan Codsiga

Xawaare sare iyo qoto dheer oo goyn ah ayaa la isticmaali doonaa marka la farsamaynayo sababtoo ah kulaylka oo daciif ah oo waraaqaha ku jira.

Mashiinka iyo jarista badeecadan waxay sii deyn doontaa boodh iyo qiiq badan. Tallaabooyin ku habboon waa in la qaadaa si loo hubiyo in heerarka boorku ay ku jiraan xadka la aqbali karo inta lagu jiro hawlgallada. Hawada qiiqa ee maxalliga ah iyo isticmaalka maaskaro boodhka/qaybta ayaa lagula talinayaa.

Go'yaasha waxaa la saari karaa qoyaan ka dib marka la mariyo, waxaana lagu talinayaa in lagu dahaadho dahaarka dahaarka leh.

Qalabka Wax Soo Saarka

Xirmada Xaashiyaha La Daabacay